A compact, portable and economical

high power inductive energy storage generator - development and application -

HEIBE

Funding: INCO COPERNICUS� Project: ERB-IC15CT970705

Coordinator:

Ecole

Polytechnique, Laboratoire de Physique des Milieux Ionis�s, Palaiseau, France,

Project manager: Dr. Peter Choi

Partners:

Ecole Polytechnique, Laboratoire de Physique des Milieux Ionis�s,

Palaiseau, France, Project responsible: Dr. Jean Larour

Trinity College, Dublin University, Ireland.

IR Project manager: Professor James Gerard Lunney

Loughborough

University of

Technology - LUT, U.K., UK project manager: Professor Ivor Ramsay Smith

INOE 2000, Magurele,

Romania, RO Project manager: Dr. Viorel Braic

High Current

Electronics Institute, Russia, RU Project manager: Dr.

Alexander Kim

INOE

PARTNER

I.

Objectives and planned actions

1.

very low ion energy ion assisted TiN thin films deposition by magnetron sputtering

� plasma

study (noble gas addition)

� film

deposition and characterisation

2.

development of a cathodic arc ion

assisted hard coating deposition system (closer to the industrial application

than magnetron sputtering system)

3.

hard coating (TiN)

deposition of electrodes for HEIBE system

4.

collection of information for data

base

5.

Life time increasing of highly

stressed electrodes of HEIBE power pulse generator by surface coating with hard

nitrides (TiN, TiAlN)

v electrodes

design, manufacturing and coating

v electrodes

tests on high power pulse generator

v surface

wear/damage investigation

v design

of optimised coatings for power pulse generator electrodes

6. Design and manufacturing of a

substrate holder for the working chamber manufactured in the first year. The

substrate holder has to provide different ion exposure angles, temperature

measurement and regulation, ion current measurement.

II.

Contribution of the partner

�Point 1

is our �traditional� field of activity and a comparison between the already

�classical� surface processing technologies as magnetron or plasmatron

thin films deposition and the newest aproaches

dealing with energetic ions to design new thin film deposition or surface

modification technologies has to be made.

Related to point 5 and, also in order to have a more accurate undestanding of different ion species influence on film

deposition process, the plasma surounding the

substrates was investigated by optical emission spectroscopy (OES) and Langmuir

probes (LP). The results are presented in the papers listed below (section IV).

The measurements done with the existing equipment will be refined using the

ordered new monochromator and Langmuir probe electronics.

In the existing magnetron deposition system with three rectangular

magnetrons, a supplementary anode electrode introduced in the plasma volume

generated by magnetrons, determined an increase with a factor of two of the ion

flux bombarding the substrate during thin film growth. As a consequence thin

films adhesion increased from Lc �

30 N to about Lc�> 45 N, exhibiting a

pronounced (111) texture. Using XRD it was determined that the most intense

peak of TiN corresponding to the (111) plane is

probably induced by the (011) plane orientation of the intermediate Ti layer

deposited before TiN deposition. On He addition to N2/Ar discharge, it was evidenced using optical emission

spectroscopy method, a higher probability of nitrogen molecule dissociation,

indicating N rather than N2+ species are relevant for stoichiometric

TiN or (Ti,Al)N

thin film formation.

Different electrodes were tested in the pulsed HEIBE ion source

having the surfaces coated with hard nitrides (TiN)

either by magnetron sputtering or by plasmatron

deposition methods. It proved that electrodes with greater thickness of the

coated layers (plasmatron deposited) displayed a

higher lifetime. The final design was established and realised for the coated

electrodes. We report good adhesion of the deposited film to the substrate

(scratch test method using a standard Rockwel tip,

with max. 90 N indentation force) and a five times

increase of the life time during high power switching in the pulse formation

devices

Point

2. A new hard coating deposition system having a large (700 x 700 x

700) mm coater box configuration was developed in INOE. The system which offers

facilities for larger substrates coating (even real industrial tools or

workpieces) is provided with 4 plasmatrons (arc)

vapor sources. The substrates can be biased (up to 200 V) allowing very high

ionic current densities to assist thin films deposition. A special lateral port

(i.d. 200 mm) was designed to fit a HEIBE prototype. The set-up will allow some

unique features: the direct comparison of effects of ion bombardment at

different energies and fluences and also the possibility to design new

dedicated applications. The plasmatron deposition

system was developed with the financial support of INOE but the HEIBE contract

significantly stimulated the decision to develop it. The deposition is made in

vacuum for metallic thin films (i.e. Ti, Cr) or, if a reactive gas is

introduced in the deposition chamber, a hard coating of nitride may be obtained

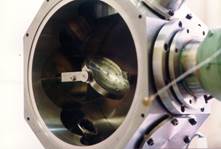

(TiN, CrN). the photo of an

arc discharge in front of one cathode. There were obtained thin films of TiN and CrN deposited on

stainless steel SS304. There were obtained thin films of TiN

and CrN deposited on stainless steel SS304.

Point

2. A new hard coating deposition system having a large (700 x 700 x

700) mm coater box configuration was developed in INOE. The system which offers

facilities for larger substrates coating (even real industrial tools or

workpieces) is provided with 4 plasmatrons (arc)

vapor sources. The substrates can be biased (up to 200 V) allowing very high

ionic current densities to assist thin films deposition. A special lateral port

(i.d. 200 mm) was designed to fit a HEIBE prototype. The set-up will allow some

unique features: the direct comparison of effects of ion bombardment at

different energies and fluences and also the possibility to design new

dedicated applications. The plasmatron deposition

system was developed with the financial support of INOE but the HEIBE contract

significantly stimulated the decision to develop it. The deposition is made in

vacuum for metallic thin films (i.e. Ti, Cr) or, if a reactive gas is

introduced in the deposition chamber, a hard coating of nitride may be obtained

(TiN, CrN). the photo of an

arc discharge in front of one cathode. There were obtained thin films of TiN and CrN deposited on

stainless steel SS304. There were obtained thin films of TiN

and CrN deposited on stainless steel SS304.

The

plasmatron coating deposition system developed in

INOE presented in the previous report, was improved by addition of a new

substrate holder, in order to apply on the substrates not only a dc bias

voltage (-100 V - 200 V) but also a pulsed bias voltage (max. 25 KV,

10 Hz, 10s). The substrate holder is vacuum tight, supports 25 kV and

max. 10 A discharge current and can rotate around its axis (in order to obtain

a better uniformity of the coating).

��������������� A multilayer structure (TiC, TiCN and TiN)

was deposited using a plasmatron discharge in

reactive atmosphere (containing C6H6, C6H6 + N2 and N2 for different stages of

the deposition process), using the above described pulsed and dc biasing of the

substrates.

��������������� Multilayers coatings, used in a

wide range of applications (e.g. optical, electronic, magnetic, corrosion

protection and wear / tribological) generally exhibit high hardness and good

adhesion to the substrate, good oxidation resistance properties, which are

impossible to obtain with monolayers. In the isostructural multilayers, due to

the crystallographic match of the neighbouring layers, special tribologic and hardness properties may be exhibited. TiN and TiC form one with another

stable solutions, in the full range of concentration of the constituent

elements. This enables to obtain Ti(CxN1-x) with the

lattice constant values ranging gradually from 0.424 nm (TiN)

up to 0.433 nm (TiC), depending on the mutual

proportions between nitrogen and carbon in the coating.

��������������� The used PVD type coating is a

cathodic arc in reactive plasma deposition (plasmatron

with dc bias voltage). Plasma source ion implantation (PSII plasmatron

with pulsed high voltage bias) was applied in the final stage of TiN deposition. In the case of PSII the plasma from the plasmatron discharge is used as well a source of medium

energy ions for implantation and of low energy ions for ion assisted deposition

(IAD).

������������������������������� The substrates

used were high speed steel ISO HS 6-5-2 (0.88% C, 4.2% Cr, 6.5% W, 5.0% Mo,

1.9% V), hardness 62 2 HRC. Different layers where

obtained for different ratios of the C6H6 /N2 reactive gases and different bias

parameters.

��������������� The X ray diffraction spectra

showed a gradual change in the lattice parameter values as the composition of

reactive atmosphere changes from pure N2 to C6H6.� Changing the dc bias value in the range 50 V

- 200 V a more pronounced (111) plane orientation in comparison with (200) and

(220) was observed for both TiN and TiC specific lines. The applied high voltage bias substrate

determined a densification of the deposited film and a finer texture with finer

crystallite dimensions, determining a higher hardness of the film. When high

voltage bias was applied TiN, TiC

and Ti specific X-ray diffraction lines were observed, probably due to the

destruction of� Ti

- C bonding due to the bombardment with medium energy ions.�

��������������� For the deposited layers,

microhardness ranging from 2400 HV (0.5) to 3500 HV (0.5) where obtained.

Scratch tests showed that there is a critical force of adhesion Fc for every

layer / substrate: TiN/ Ti(CxN1-x),

Ti(CxN1-x)/ TiC and TiC/

HSS. The best adhesion (higher Fc) was obtained for TiN/

Ti(CxN1-x) and the lower one for TiC/

HSS. The best results were obtained for the high content of nitrogen (10% -

30%) in the mixed reactive deposition atmosphere. The critical force values

obtained were in the range of 55 N - 68 N, compared with the usual values of

about 45 N for TiN thin films previously deposited.

Point

3.� Due to the existing

experience related to hard coatings deposition some tests of coated electrodes

for HEIBE system are in development. These tests are aimed to improve the lifetime

of highly stressed electrodes surfaces during high power switching in the pulse

formation devices.

Another contribution of INOE - Low Energy Ion Beam Laboratory to

the development of a new HEIBE system in LPMI Palaiseau

was the mass spectrometric leak control of the vacuum chamber manufactured by

N&V.�

Point

4. Being a milestone of the contract, the development of a

reliable, high speed e-mail/internet link was very

seriously considered by INOE. The existing Copernicus HEIBE contract triggered

the development of a new e-mail/internet link connecting the laboratory and than the whole INOE network by high

speed microwave communication system directly to the satellite link

installed in the Polytechnical University in Bucharest. In the third and last

year of activity for the present contract the data base software developed in

INOE was completed with a�

number of� 500 papers

related to the high energy ion beam modification of surfaces. The main

information (titles, authors, key words, journal, abstract) is stored in

computer and may be easily accessed using the new created DataBase-INOE.

Point

5. In this first year having internet facilities and travel expenses

ensured by the contract, approx. 300 papers related to the above

mentioned topic were collected. The main information (titles, authors, keywords,

journal) is stored in computer and may be easily accessed. Also, the created database

made possible to find out about some books recently published, related to thin

films deposition in vacuum by PVD techniques and surface processing in plasma

or with ions. They were purchased from other financial sources.

As

a result of the already existing data base, a short review of literature

related to �Material Aspects of Corrosion Protection by Ion� Beam Techniques� is presented in

annex1 and annex 2.

���������������

Point

6� Substrate

holder designed and manufactured.

Publications

and papers

�

Modified dc magnetron sputtering

configuration investigated by optical emission spectroscopy and related TiN films properties, V.Braic,

M.Braic, G.Pavelescu, C.N.Zoita, G.Musa, Balkan Phys.

Lett, vol. 6/7 1997

�

Influence of He, Ne and Kr

addition in reactive Ar/N2 dc magnetron

plasma on TiN thin films, M.Braic, C.N.Zoita, V.Braic, A.Kiss, M.Popescu, G. Musa, Vacuum, 53 (1-2) , pp.41-45.

�

Langmuir probe investigation of a

plasma produced in a dc magnetron system, V.Braic,

M.Braic, C.N.Zoita, A.Kiss, Rom.Rep.Phys., vol. 49,

nr.5/7, 1997

�

Magnetron discharge - dedicated

spectroscopic investigation for TiN thin films

deposition, M.Braic, V.Braic, C.N.Zoita, A.Kiss, Rom.Rep.Phys., vol. 49,

nr.5/7, 1997

�

������ Carrier

density and temperature measurement in a pulsed hydrogen plasma generated by a duopigatron ion source, V.Braic, C.Zoita, A.Kiss, M.Braic, G.Pavelescu, Rom.J.Optoelectronics,

vol.6, 4. p. 13-16 (1998)

�

M. Balaceanu,

E. Grigore, G. Pavelescu, F. Ionescu , J. P. Roger,

Optical characteristics of carbon nitride films prepared by hollow cathode

discharge, J.Optoelectronics and Advanced Materials,

Vol.2, N0.4, Dec 2000, p351

�

M.Balaceanu,

E.Grigore, F.Truica-Marasescu, D.Pantelica, F.Negoita, G.Pavelescu, F.Ionescu, Characterization of carbon nitride films

deposited by hollow cathode discharges process,�

Nucl. Instr. & Meth. Vols. 161-163, March

2000, p 1214

�

J. Larour,

P. Choi, J. Rous, S. Dine, S.L. Yap, C.S. Wong, G. Pavelescu

, M. Favre, A. Guilbert, Ion Beam Measurements on a Modified Plasma

Focus, APS Plasma Physics meeting, October 25, 2000, Canada.

�

P.Choi,

J.Larour, G.Pavelescu, V.Braic, C.Dumitrescu, M.Braic, J.Rous, Effect of

Irradiation with Pulsed Nitrogen Ions� of

TiN Coated Austenitic, ROCAM 2000

�

Influence of noble gas addition in

low frequency driven magnetron discharge for TiN thin

films deposition, M.Braic, C.N.Zoita, V.Braic, A.Kiss, G. Musa, VI-th European

Conf. on Atomic and Molecular Physics, ECAMP �98, Siena. Italy, July 1998

�

Plasma diagnosis of a low

frequency driven magnetron, V.Braic,

C.N.Zoita, M.Braic, A.Kiss, G.Musa, X-th Conference on Plasma Physics and Applications, Iasi,

Romania, June 1998

�

Influence of He addition in

reactive dc magnetron plasma for TiN thin dilms deposition, M.Braic,

C.N.Zoita, V.Braic, A.Kiss, G.Musa, X-th Conference on Plasma Physics and Applications, Iasi,

Romania, June 1998

�

Langmuir probe diagnosis of a

pulsed duopigatron ion source, V.Braic, C.N.Zoita, A.Kiss, M.Braic, X-th Conference on Plasma Physics and Applications, Iasi,

Romania, June 1998

�������������� Influence of a pulse superimposed

on a dc reactive�

magnetron plasma for TiN thin films

deposition, M.Braic, V. Braic,

C.Zoita, A.Kiss, 18-th

General Physics Conference of the Turkish Physical Society, October 1998,

Alanya, Turkey

�������������� Influence of the added He and Ne

to N2 on the barrier discharge emitted N2(B-X) band

�G.Musa,

I.Borcoman, E. Finantu, C.Bob-Surdu, M.Andrei, M.Braic, ESCAMPIG 14, Malahide, Ireland, European

Conference Abstracts, Vol. 22H, p.88-89, ed. D.Riley,

C.M.O. Mahony, W.G. Graham, Belfast 1998

�������������� Gas Nature Influence on the

Langmuir probe Characteristics in a Pulsed Duopigatron

Ion Source,� 18-th

General Physics Conference of the Turkish Physical Society, October 1998,

Alanya, Turkey

�������������� Dependence of the hard coatings

properties on the substrate geometry and dimensions M.Balaceanu, G.Pavelescu, A.Manea, A.Popescu, E.Grigore, F.Marasescu-Truica,

5th Int. Union of Materials Research Societies - Int. Conf. in Asia (5th

IUMRS-ICA-98), India

�������������� Influence of ion bombardment on

amorphous carbon (a - C) film characteristics M.Balaceanu, E.Grigore, G.Pavelescu, F.Truica-Marasescu, G.Galeata, V.Braic, Xth Conference on Plasma Physics and

Applications, June 1998, Iasi, Romania